Electrical Hazards

6. Risks when Working on High Voltage Installations

When working on high voltage installations (voltages above 1,000V), safety measures must be maximized from both the informative and protection point of view, as the hazard is much greater and hence the likelihood of suffering a serious accident is also greater.

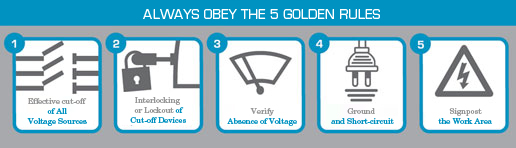

Fulfilment of the “Five Golden Rules” is thus mandatory; the first three of these rules are also mandatory in low voltage work, while the last two are recommendable.

RULE No. 1:

Opening with visible cut-off of voltage sources.

When the design of the cut-off elements does not allow the cut-off to be visually appreciated, these elements are to be equipped with devices that guarantee effective cut-off.

RULE No. 2:

Interlocking or lockout of cut-off devices in the open position, employing mechanisms that impede unauthorised personnel from actuating these devices, and signalling said elements with a hazard warning indicating that it is forbidden to manipulate them.

When their lockout is impossible, it will be necessary to mark them with a hazard warning indicating that it is forbidden to manipulate them.

RULE No. 3:

Acknowledgement of the absence of voltage in all the conductors that penetrate a work area.

The correct functioning of the tester must be checked before and after the operation.

To check the absence of voltage, the installation is to be considered live. The operator carrying out the work must therefore always use two of the following three safety elements at the same time:

- Insulating rod.

- Insulating gloves.

- Insulating stool or mat.

All these elements must be duly certified for the installation voltage.

RULE No. 4:

Grounding and short-circuiting of all the uncharged conductors entering into the work area.

If fixed earthing switches are used, it is obligatory to check that their blades have fully closed. If fixed points are not available, make sure that the earth clamps make good Contact.

RULE No. 5:

Signal the work area with the mandatory safety signs and cordon off the area with barriers designed for this purpose.